Dyno Cheating:

As this thread states, its purpose is to discuss dyno cheating, how it's done, and how to prevent it. I'm hoping that people familiar with different dyno brands will lend their expertise to this discussion to help expose and prevent dyno cheating. As new dynos are discussed, I'll roll up the results into this message. If there's enough interest in this thread, I'll eventually make it a sticky.

Overview:

Many dynos, but probably not all of them have one or more ways to cheat the results. The most common way to cheat is to set a "Correction Factor" -- which is a number that is used to multiply the results before they are displayed on the screen. But other ways of cheating exist as well. It's possible to cheat by manipulating the pressure sensors to read higher or lower when the need arises. Hopefully this thread will expose some of these techniques and give people ways to catch the cheaters.

Table of Contents:

| Do Real World Results Even Matter | Click Here |

| Dynapack | Click Here |

| Dyno Dynamics Overview | Click Here |

| Dyno Dynamics Exposed (Part-1): Cheating by Correction Factors | Click Here |

| Dyno Dynamics Exposed (Part-2): Cheating by Accidental Over Correction by Inlet Air Temperature Probe | Click Here |

| Dyno Dynamics Exposed (Part-3): Cheating by "Gear Ratio" | Click Here |

| Dyno Dynamics Exposed (Part-4): Cheating by Incorrect strapping | Click Here |

| Mustang Dyno | Click Here |

Do

"Real-World" results even matter?

The short answer is: they do, but not in this discussion.

Some people would say that real-world results are the only performance metric

that matter, and that a dyno is just tool to provide an anecdotal measurement of

performance relative from one set of changes to the next. To people trained in

scientific methods, it's painfully obvious that this view is exactly opposite of

reality: real-world performance is the anecdotal performance metric, not the

dyno.

Real-world performance doesn't sell parts: dyno results do. If real-world

performance was the penultimate performance metric, then you’d see aftermarket

manufacturers publishing 0-60mph, ¼-mile, and 60-130mph times to sell their

parts instead of publishing dyno charts. Most people realize that real-world

performance is dependent on so many factors completely outside of their control,

that these “real-world” tests are practically meaningless – making their results

nothing more than anecdotal in nature. That’s why they, and the manufacturers

have always trusted the dyno to sell their parts. And it’s because of the

dependence and trust in the dyno, that cheating dyno results is so dangerous.

Because of the dependence on a dyno, cheating the results is a fraudulent way to

make a company's product look better than it actually is, better than their

competitors, and thus increase their sales. It shouldn't even need to be stated

that the buyer has a right to know what he's buying, and not to be defrauded in

this manner.

The following list is a small sample of the problems with real-world testing and

why the results may be interesting, but are scientifically meaningless.

- "Real-world" performance does not tell you how powerful your motor is, and doesn't even do a good job of telling you how well your car performs in "the real world."

- The drag race guys love to tell you that the 1/4-mile trap speed is a true measurement of a car's power -- as the trap speed will not change significantly with driver ability. Yet the same drag race guys cry foul every time I suggest that I could coast 5-seconds between gear shifts to disprove their theory.

- 1/4 mile times, and 60-160mph times are significantly dependant on driver ability and the conditions at the moment. My own 60-130mph times have changed by a whopping 1.5 seconds without making a single change to my car. This is a clear indication that driver ability and instantaneous road and weather conditions play a much larger role in the results than the "real-world advocates" have admitted.

- A clutch delay valve will not add or subtract one single horsepower to the motor, but deleting it will shave one-third to one-half a second from a 1/4-mile or 60-130mph time.

- Gasoline quality, oxygenation, octane, ambient temperature, altitude, humidity all affect a motor's performance on a given day. "Real-world" measurements don't take this into account, but dyno’s do.

- Vehicle weight also plays a role. A guy who removed 200 pounds from his car will naturally "perform better" than a guy who didn't -- but he didn't add a single horsepower to his motor.

- Then of course, there's those pesky big diameter wheels and tires that look great, but suck your performance away. Again, they don't add or subtract a single horsepower to/from your motor, but they do affect your "real-world" performance.

In all the ways to measure a car's performance, "real-world" results are

probably the least scientific. They are largely dependent on driver ability,

gasoline quality, road conditions, atmospheric conditions such as temperature,

altitude, humidity, wind direction and wind speed. A dyno takes these factors

into account and tries to eliminate most of them. If "real-world" performance is

the one true performance metric as these advocates claim, then it needs to be

measured with the same driver, on the same day, on the same stretch of road,

with the same gasoline, with the same wind speed and direction. Yet even if all

of these things were done, the results are not guaranteed to be scientifically

accurate.

So this brings us back to dyno performance and the need to get results without

being cheated. Real-world tests are just another tool, but by no means are they

without many, MANY flaws and variables. As I’ve stated, there's nothing even

remotely scientific about real-world testing. Dyno's are intended to be

scientific measuring tools. Dyno cheating is a way to defraud the public into

buying a product that has less performance than is claimed by the manufacturer –

thus to sell more parts. And it's that last part -- defrauding the public for a

profit motive -- that makes this topic so important that it shouldn't be

trivialized and swept under the carpet.

Since the Dynapack is a hydraulic load-bearing dyno, it's pretty hard to cheat it. Since it operates on hydraulic pressure and uses this pressure to measure torque, I'm not sure if it can be cheated. But just as fast as I say this, I wonder what the effect would be if the pressure sensors were modified -- either smaller or larger -- to effectively cheat. I'm wondering this because there is one Dynapack in Southern California that many dyno operators complain about. They claim it reads very high -- higher than other dyno's, and even higher than other Dynapacks. I've looked at a few Dynapack log files generated by this company, and nothing looked unusual to me. Yet I have to admit, the results I've seen produced from this shop are significantly higher than the three other Dynapack's I've used on my own car. Once the ECU tuning is completed on my Stroker-M3, I plan to dyno at one of my regular dyno shops in Orange County, then travel up the road to the other shop and dyno on the same day with the same tank of gas. If my results are significantly different, then I plan to post these results.

Dynapack's can also be programmed with a correction factor. The CF is entered into the dyno operator's setup screen. This factor appears in the log files, and is also displayed on the screen for each dyno run. So if a Dynapack operator is using a CF to adjust the results, it should be clear to anybody that gets a printout.

Dyno Dynamics are very easy to cheat. The software contains a hidden CF field that the user never sees, and isn't printed on the screen. Just because a dyno operator changes this value from 1.0 to something else, doesn't necessarily mean they are cheating. If they set it, and leave it forever and never change it, then it doesn't invalidate their dyno results, it just makes the results appear higher than another Dyno Dynamics dyno. If the operator changes this value between runs, then obviously they are cheating. But if they leave it alone, then I wouldn't be calling any type of foul play.

One company in Southern California sets their CF to 1.13 -- thereby multiplying all of their results by 1.13 before displaying on the screen. They aren't doing this to cheat, but instead want their dyno to report similar results to the various Dynojet dynos in the area. But if you compare their results to other Dyno Dynamics dynos, you will notice they always read higher.

But there's a much more sinister way to cheat with a Dyno Dynamics. The DD Dyno has a pressure sensor that is exposed. If you apply weight to this sensor, then all of the results will read higher. An operator could easily cheat and give inflated results for his own products if he were to run the baseline normally, then place a weight on top of the sensor (or even stand on it). Doing this would cause the end results to look far better than they actually are. Just think how this could be abused if a dyno operator was using this technique to display the gains made on his intake, ECU tune, pulley, or exhaust. The baseline would look normal, but the purported gains would look enormous and exhaggerated.

I know older DD dynos have this sensor exposed, but I'm not sure if newer ones do. I've seen pictures of newer DD dynos, and it's possible that DD enclosed this sensor to keep it from being manipulated. Hopefully people reading this thread and familiar with newer DD dynos can shed some light onto this subject.

Basic Guide

about Dyno Dynamics and it's Cheat Methods (by M3Post user Sal@Evolve)

This is a basic guide, correction factors have been explained in a very basic

way so everyone understands it. This basic guide has also been kept as short as

possible so people don't lose interest in reading it.

PART I - Cheating by Correction Factors

- Ambient Air Temperature, Barometric Pressure, Relative Humidity

Before we talk about this we need to understand what correction factors are

and why they are present in dyno software.

It is surprising how many people think they are there just as a built in tool

for operators to make the figures up. Far from it.

Correction factors are all about standardisation.

Dyno Dynamics Correction Factors:

- Barometric Pressure = BP

- Relative Humidity = RH

- Ambient Air Temperature = AT

- Inlet Air Temperature = IT

Some general facts:

- An engine will make less power at high altitudes than at low altitudes.

- An engine will make less power with higher air temperatures

- At higher altitudes the BP is of a lower value

- The reference point for these correction factors is set - please see SAE.

- Static correction factors are as good as not having them at all. There are many companies which input 1013mB all year round. This is pointless.

An engine will not make the same power from one day to another as weather conditions are changing. Without correction factors dyno readings from day to day are not comparible. Therefore the difference in an ECU tune tested on a day which is different to the day the base run was taken should be ignored if correction factors are not present.

A very well explained internet page about correction factors can be see on

the below link

http://wahiduddin.net/calc/cf.htm

Correction factors allow a car to make the same power on a dyno no matter what the atmospheric conditions are. This can only work if the ACTUAL conditions are recorded at the time of the dyno test. When I mean time I literally mean on a minute to minute basis as room temps where dyno's are located can vastly change within a short space of time.

There are many Dyno Dynamics owners, like us, who test the same cars all year

round keeping constant the fuel type used and keeping the cars in good health.

We allow the Dyno Dynamics weather station to take the AT, BP and IT. We get

almost exactly the same corrected WHP every time no matter if it's mid summer or

winter.

So if we upgrade a part of the engine/ecu anytime during the year we will know

it's effect.

So the correction factors are there to give us consistency and allow us to compare the results no matter when they were done. It works and works well.

The problem - dyno operators know how these correction factors work and they change them where they can to show larger increases on power output.

To illustrate this we will use some example:

Car: BMW E92 M3

Actual Conditions: BP=1013, RH=50% and AT=25 Degrees C

The Dyno Dynamics weather station reads exactly this and the car makes 340WHP.

If we change the BP to 980mB the software will add power because at a higher altitudes the engine will make less power. But because this is a false reading the car is now going to make more power.......more false power because the mechanical efficiency is being calculated wrong.

So by changing these readings the correction factor also changes and therefore the output changes. By changing the readings from actual or whatever they were on the previous run you can manufacture what ever output you want! It's that easy!

How do you make sure this isn't happening to you?

Very simple.

- On the later Dyno Dynamics machines ask operator to press key 'A' and make sure the weather station is set to the 'ON' position. As long as this stays on then you have nothing to worry about (other than inlet air temp which is discussed in the next section).

- On the earlier machines the weather station is remote and the operators have to input the values themselves. Ask to see the 'BAR SCREEN' and also what the weather station is 'ACTUALLY' reading. Do this before every run. As long as what the weather station is recording = to what's entered, you have nothing to worry about.

- If the operator chooses to keep his values static then just ask to see the BAR SCREEN before every run. As long as the values are the same your ok. This method of keeping the values static is a total waste of time as it's the equivalent to having no correction factors.

In case 2 please ask to see the weather station and make sure it's not got anything put ontop of it between runs.

The Dyno Dynamics software is as far as I know the only one which has a probe which is to be placed in the inlet tract to measure actual air intake temperature.

This is one correction factor which is open to huge abuse and also causes many innocent mistakes to be made from operators.

This probe reading gives us an additional correction factor - the way it works is simple, it takes the ambient temperature and adds back power based on the difference in inlet temp and ambient temps.

If the probe is placed inside the airbox and is measuring the temperature of the air (and not the sidewalls of the airbox!) then it's all good.

If the probe is placed elsewhere (radiator, exhaust manifold or anywhere hotter than the airbox) then your being played - SIMPLE.

How do you make sure this isn't happening to you?

Just ask to see the position of the inlet probe and make sure no one changes it's position in between runs!

If your being handed a graph then ask to see the difference in AT and IT. If it's the same your ok. If there is a vast difference between AT and IT between the two runs then you should have doubt.

The reason I say you should have doubt and not actually make an accusation is because it's an area which can be overlooked so easily. The probe can move from measuring the air to the temperature of the sidewall of an airbox. The dyno operator may not notice this (they normally have lots of things to look at!) and overlook this over correction.

IT can be seen on the BAR SCREEN at all time. So can AT. You will see IT dropping as a cooling fan is powered on and as the engine ingests ambient air.

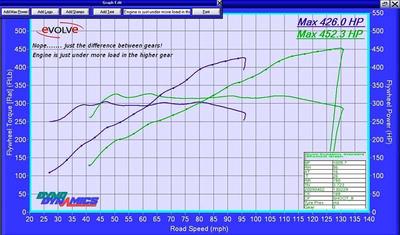

PART III - Gear Used (by M3Post user Sal@Evolve )

It is common knowledge that an E92 M3 will make considerably more WHP in 4th than 3rd gear.

This is an actual graph done by us to show the difference!

3rd is the correct gear on a Dyno Dynamics. Please do not ask why at this stage as this is not the point. We are looking at consistency ONLY.

It is very easy to calibrate the dyno for both gears and show a false gain in power.

How do you make sure this isn't happening to you?

Simply ask for a print out with road speed on the lower (X-Axis). 3rd gear reaches approx 90-100mph, 4th gear will be 125-135mph.

Below graph is of the exact same as above but with road speed replacing RPM's on X-Axis

(Please ignore comment about load - this was an assumption which is not correct)

If your not concerned about which gear is the right gear then just make sure the

same gear was used.

Note:

Flywheel power on Dyno Dynamics is just Wheel Horsepower multiplied by approx

1.16. I say this because most of you are not used to seeing fly figures. It's

the exact same graph with just a % added everywhere.

Part IV - The Climbing

Effect and Strapping (by M3Post user Sal@Evolve)

How hard a car is strapped down will have an effect on all dyno's including the

Dyno Dynamics.

If a car is strapped down hard on a base run and then 'looser' on the one after a small-medium difference will be shown in the output.

The problem here is that a car may be totally non-moving on a dyno and this can be done without you ever knowing the strap tension. How are you going to know how hard a car is strapped if it's not moving around?? No way of telling!

The Solution is simple and we use it.

Allow the car to mount the front roller completely leaving the rear one. Once the car has mounted the front roller, it doesn't matter where it sits on it because the reading will be the same.

So not scare the hell out of customers we just allow them to leave the rear roller by about an inch.

The overall benefit is that you achieve maximum grip and strap tension doesn't come into it. All the dyno operator has to do is hold the car back once it's moved forward a very small amount.

You totally cancel out the effects of strap tension!

With all of the above you should have no issues. There are no other hidden secrets other than the obvious ones:

- Not pressing the throttle all the way down on the base line run (difficult to deal with!)

- Applying the brakes lightly on the base line run (Stand at the rear of the car if it's safe)

- Changing the ramp rate between runs - will be displayed on your print outs.

Thanks for reading. I will post up some further info about graphs and shootout mode also.

Mustang Dyno (by M3Post

user 'masitr')

Parasitics file

Mustang Dyno's can be cheated by changing the parasitics file. This file holds the inertial information for your dyno specific model. The parasitics are different across their product line since they use different size rollers, etc. for different models.

Althought they use different files this is done to standardize the output numbers threw their product line. I guess this would be similar to the CF factor for the Dynapak, but is a main caibration file for the dyno and not entered by the operator for a specific vehicle.

To the best of my knowledge the only reason you are allowed to change the parasitics file is for one of Mustangs Key features. Unlike Dynojets you can caliblrate the parasitics file specifically to a vehicle for the most accurate results. Most of us use the standard file (factory Calibration) for all vehicles. But I have been on one Mustang that was calibrated to Dynojet numbers as that is what their local competitors use.

Tach Signal

Minor variations in Tach signal smoothing and RPM pickup variance from the source will shift the power curve right or left.Since HP is calculated from RPM this only natural. It Doesn't always change peak power but will change the curve.

Test procedures

These may be the obvious ones. Different operation Temps, change or addition of fans, tire pressures, wheels/tires, etc. Basically any variance from run to run will skew results.

These are some of the major ones that I have found.